Euplectella aspergillum is a beauty. It is a greyish-white sponge that is found in the deep waters of the Pacific. Loosely-woven and bottle shaped, they grow in clumps and keep dancing with motion of the waters. The locals know them as ‘venus flower basket’ and are a spectacle to behold.

Deepak Sharma put a sample of Euplectella aspergillum on his worktable and began regarding it keenly, with folded hands. But its aesthetics appealed little to him. He was more concerned about the ying-yang of the lattice structure. There were vertical and horizontal struts, making several little squares. But while some squares had diagonal struts (closed cells), others didn’t (open cells).

To most of us, this may not mean anything—we wouldn’t even have noticed these features — but for Sharma, who is doing his doctorate in mechanical engineering, and his guide, Prof Somasekhar Hiremath, of IIT-Madras, saw this peculiar cellular architecture of the Venus flower basket as nature’s way of giving the sponge properties of buckling resistance and impact and vibration absorption.

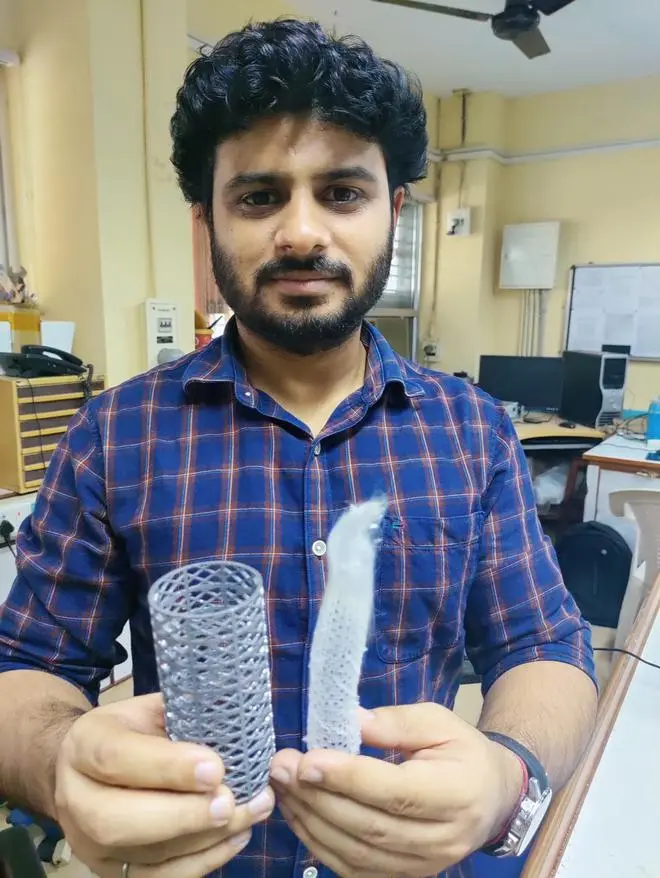

Deepak Sharma holding a ‘Venus flower basket’ and a functional material

Sharma pulled out a sheaf of papers and made some drawings and scribbled some points. These became the feed material for 3D printers. Presently came an assortment of weird objects, some cylindrical, some cuboid, made of weirdly named polymers. He and Prof Hiremath tinkered with the cellular architecture, making some struts soft (with thermoplastic polyurethane) and others hard (with poly lactic acid). These are meant to impart the engineered material different properties such as energy absorption. These engineered materials are the basic building blocks that can eventually be adopted into automobiles, space, armoured vehicles, bio implants, and so on.“Our bio-inspired structures showed better energy absorption performance than the most commonly used foams and honeycombs for industrial applications,” says Sharma.

“These structures can be incorporated in the aero-engine components to significantly reduce the weight, increase vibration absorption and for improved heat dissipation control,” Prof Hiremath told Quantum.

Nature’s wonders

Well, this is an over-simplified description of Deepak Sharma’s work, which actually took years from start to finish, but the underlying theme is an evolving branch of engineering, called bio-inspired materials. (B L Zhou notes in his paper on bio-inspired study of structured materials, that the term “bio-inspired” may be better than the terms “bionic” or “biomimetic”, since the former is relatively easy to be accepted.)

Deepak Sharma holding a ‘Venus flower basket’ and a functional material

The hard back of a beetle, the wings of a butterfly, the hairs of sea skaters, the natural spider silk—the list could be endless—all have messages for engineers to make new materials. The beautiful colours of butterflies come from their microstructure interacting with light. Spider silk, for example, has ultra-high tensile strength. In an article in Chemical Engineering Journal, a group of Chinese scientists says how they copied the “nanoconfinement effect of hydrogen-bonded crystalline β-sheets on the soft amorphous protein matrix” and used the same nature’s trick to create similar material with soy proteins and tannic acid, an inexpensive plant-derived polyphenol.

Another student-researcher in Prof Hiremath’s lab, Priya Ranjan, has drawn inspiration from the rather peculiar, crescent-shaped structures on the insides of a pitcher plant — a plant with pitchers into which insects fall and are duly digested — to give a better surface texture to the cutting edges of machine tools. Ranjan has been able to arrive at the exact dimensions of the ‘crescents’ etched on the machine tools that would give the best results. Surface texturing is altering the topography of the cutting tool’s surface by micro-etching different geometrical patterns on it — the geometrical texture generation enhances the tribological characteristics (friction, lubrication and wear) of the interfaces between the tools and the workpiece.

Copying nature

‘Bio-inspired materials’, as a science, is not really new, but is gathering momentum, as researchers are seeing that there is so much to learn from nature, to partake of the knowledge accumulated by nature, by its own trial and error, over billions of years. But what happened to accelerate research now? One reason, scientists say, 3D printing. Earlier scientists didn’t know how to copy nature, but with 3D printing, you can make anything, no matter how complex the structure.

It is not clear as to how much the bio-inspired materials have made their way to the industry, because the distinction between bio-inspired materials and others is not sharp. Some cellular structural materials, such as those of honeycomb structures, are well in use in the industry. But it is safe to say that what has seeped into the portals of the industry is practically nothing compared with what is available.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.