For those who have seen Priya Prakash, Managing Director of Bengaluru-based start-up Eco Pallet, carrying pallets to convince customers, she appeared like a “lady Hercules”.

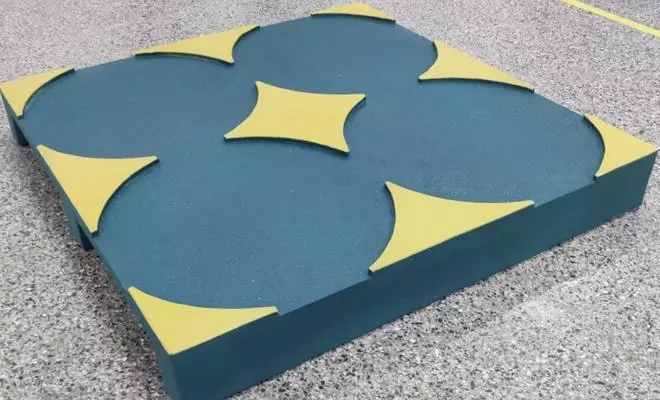

This is because these pallets, basically a packaging material, usually weigh at least 30 kg but the secret of Prakash carrying them is that they are hardly 4 kg. Eco Pallet, founded in 2015, has begun selling these sustainable light-weight pallets, which have an environmental impact, economical impact and social impact.

Priya Prakash, Managing Director, Eco Pallet

In the short period of launching these pallets, mainly from post-consumer recycled wood, Eco Pallet has about 40 customers including Mahindra Logistics, YCH Logistics and Wexford Laboratories. “Our pallets even go abroad and are reused there,” says the company’s MD, a first-time entrepreneur whose company began its journey by buying a patent of a pallet made from thermocol from a Hyderabad company. “Priya (Prakash) is probably the only female entrepreneur in the pallet industry which is very male-centric. It is not only top management but by and large the sector including the factories and people involved, it is very male-dominated,” said Joseph Franklin, CEO, Eco Pallet.

Once Eco Pallet founders bought the Hyderabad firm’s patent, it was a “love at first sight”. Though thermocol is light, if the right materials are added it could become a pallet that can bear more weight and be eco-friendly too. “When we started selling these, the pharma industry welcomed it. But we couldn’t scale it up as it catered only to a niche market,” Priya Prakash said.

“We couldn’t really push it in FMCG or other sectors apart from pharmaceuticals. It wasn’t a possibility,” Franklin said.

He said pallets, which act as a surface on which almost all raw material and finished products are transported or stored in warehouses, are mostly made of wood or plastic. Our pallets were ideal for export as our 4kg pallet can hold up to one tonne in comparison to a wood export pallet weighing 15-18 kgs, but were not meant for storage purposes.

Following the thermocol pilot, Eco Pallets turned to refiguring wooden pallets, said Franklin. “Instead of using new wood, we used recycled wood that people discard as scrap We use post-consumer recycled wood to make pallets and spray it with our patented technology chemical, we have been developing this process over the past 3-4 years,” he said.

Joseph Franklin, CEO, Eco Pallet

The chemical, which is basically poly urea, makes the pallet fire retardant, waterproof, antifungal, temperature resistant and antistatic, Priya Prakash said, adding that the carbon footprint was the biggest game changer for the company’s pallets, which are of 3 kinds — plastic, wooden and EPS. ““If you have to make a wooden pallet weighing 23kgs, carbon dioxide (CO2) emissions are roughly 8-13 kg. The CO2 emissions to make one plastic pallet is anywhere between 90-110 kgs. So, when we made our LCA for EcoLife Pallet the carbon emissions were just 0.2kg. So, the ecological impact that we are bringing to the table is massive,” Priya Prakash said.

The shelf-life of a wooden pallet is only 12-18 months. ““We found using EcoLife Pallet could increase the shelf-life to five years without any repair. We decided to go for Post-Consumer Recycled Wood because we were troubled by the fact that 15 billion trees are lost due to deforestation every year and somewhere we will also have to cut a tree to make a pallet,” the company’s MD said.

“We looked at Post-Consumer Recycled Wood because its market is as big as the wood market. When we did our processing with wood and hermetically sealed the pallet with spray, the weight bearing capability increased and became ISPM (international standards for phytosanitary measures) compliant too. To reconfirm we also got life cycle assessment and certifications done,” she said.

Sustainable

Thus, the pallet became a sustainable one with the circular economy with the best part being a tree need not be planted but recycled wood can be reclaimed and upcycled into pallet. Eco Pallet manufactures its products from scratch at its unit in Doddaballarpur near Bengaluru in Karnataka.

From the manufacturing unit, the pallets find their way to other parts of the country and world. “Our pallets are lightweight and certified by agencies such as Indian Institute of Packing. So it is a one-way pallet which can go from here to another country and then can be reused and recycled there,” she said.

In terms of trees, mainly pine wood which is used for wooden pallets, it takes 19 years to grow one. “You will be able to make 40 pallets, say for example the 1,200 mm size, from one tree. After 12-18 months, around 32 pallets go into the landfill and eight pallets are salvaged,” Priya Prakash said.

By using scrap wood, there is no need to cut a tree for pallets. In India, about 70 million pallets are used annually with the wood coming from New Zealand or Uganda. It also comes now from Australia or Canada as pinewood pallet supply from Ukraine stopped, she said. “Our pallets make transportation easy. It makes a huge difference in cargo weight, where goods are charged on a per kg basis,” said Franklin.

“We are cost-effective too. The traditional pallets cost ₹2,000 and then firms have to pay ₹200 annually as annual maintenance cost. Each of our pallets costs ₹2,500-2,800 and we give a seven-year guarantee,” Priya Prakash said, adding that the product is tested for various parameters including for polyfluoroalkyl substances.

She narrated an anecdote where YCH bought a good number of the company’s pallets for three months and in the fourth month it reported that the pallets were not breaking and it would not need to buy more. “That’s the amount of savings for the company and for the environment. Unfortunately, they wouldn’t need new pallets, but we are very happy to lose orders from such customers,” the company’s managing director said.

When it started, the problem for Eco Pallet was that it found it difficult to make people, especially the purchase department staff, understand the overall long-term savings. including the environmental benefits, said Priya Prakash. But today, people understand sustainability and the need to stop deforestation, she said, adding that the company would like to work with the government, specially the Food Corporation of India (FCI), in storage of foodgrains. “We want to change the current storage method of cover and plinth and get to use these pallets. We have also been invited by governments in the US and Finland. UAE is another country we are looking at,” she said.

Using pallets would stop moisture or water seeping from the lower part of the wood dunnage used by FCI, into the jute bags in which foodgrains are stored. “Once the government looks into our pallets, these problems can be solved,” Priya Prakash said, adding that coffee is another area the company is looking at.

Comments

Comments have to be in English, and in full sentences. They cannot be abusive or personal. Please abide by our community guidelines for posting your comments.

We have migrated to a new commenting platform. If you are already a registered user of TheHindu Businessline and logged in, you may continue to engage with our articles. If you do not have an account please register and login to post comments. Users can access their older comments by logging into their accounts on Vuukle.